-40%

Slow Speed KIT Walker Turner Delta Atlas Craftsman Drill Press 3 1/8" ID

$ 527.47

- Description

- Size Guide

Description

Note, item temporarily on hold due to critical part shortage. Check back in a week.Note, photo's show a smaller drill press as an example. This item is a pulley and adapter to help reduce speed. It includes a special mount to fit a column with a 3 1/8" inside diameter. Most drill press of this nature are large like in the 20" range. This is a slow speed pulley assembly and not an entire drill press. Read it all.

Slow speed drive system fits entirely inside many belt covers, a Delta example is shown. Reduces RPM at chuck. Slower cutting speeds work better for metals. Larger diameter cutters such as hole saws, paddle and Forstner bits cut better with less heat and wear when turned at proper speeds. Small diameter bits require higher speeds. This pulley while capable of cutting your final output speed in 1/2 is also capable of doubling it making bits under 1/8" must less fragile. Add about 0 value to your vintage American iron.

Note: Does your Walker Turner motor mount include a boss for an overarm style speed reduction pulley? As you can see this column mount style fits my 900 Series just fine with no need to cut off the factory boss or flip the motor mount plate. Belt sizes I used noted below.

The column adapter has a socket head driven spreader acting like an internal collet to snug the adapter against rotation in the column. Only snug until you cannot rotate by hand. No more pressure is needed as there is little or no operating force trying to move it. As shown, the adapter is positioned generally so bushing is to one side of press and pulley yoke is swiveled across center of the column tube towards the other side of drill press. This keeps it from getting too far off center to interfere with belt guards. It fits all my drill press's with guards. One is shown. I have no idea what dimensions yours are.

1) Your machine MUST have a column with 3.125" (3.1/8") nominal bore. (.032" over or under is OK) This is typical of many drill presses with 3.5" columns.

If you need to fit different inside diameter, please contact me.

2) The column must be capable of protruding through the top of the head casting. (See caliper photo.)

3) Made for

4 groove pulley system

requiring 1/2" belts or 4L belts. (Converts your 4 speed into a 12 speed with both slower and faster speeds.)

4) Flipping the motor drive pulley over is required. All of them I have seen can be flipped without machining. I have not seen yours.

5) Adjusting the head height on the column is required to find best belt alignment. Don't worry, V-belts can be run very far out of alignment with no issues. This is not a sensitive setting.

6) Your belt guard (if so equipped) bottom or base plate must not cover the drill press column. If it does, a hole must be cut approximately 4" in diameter to allow un obstructed access to the the tube opening. Adjusting the pulley height may require slightly raising or lowering the drill press head on the column.

This item includes:

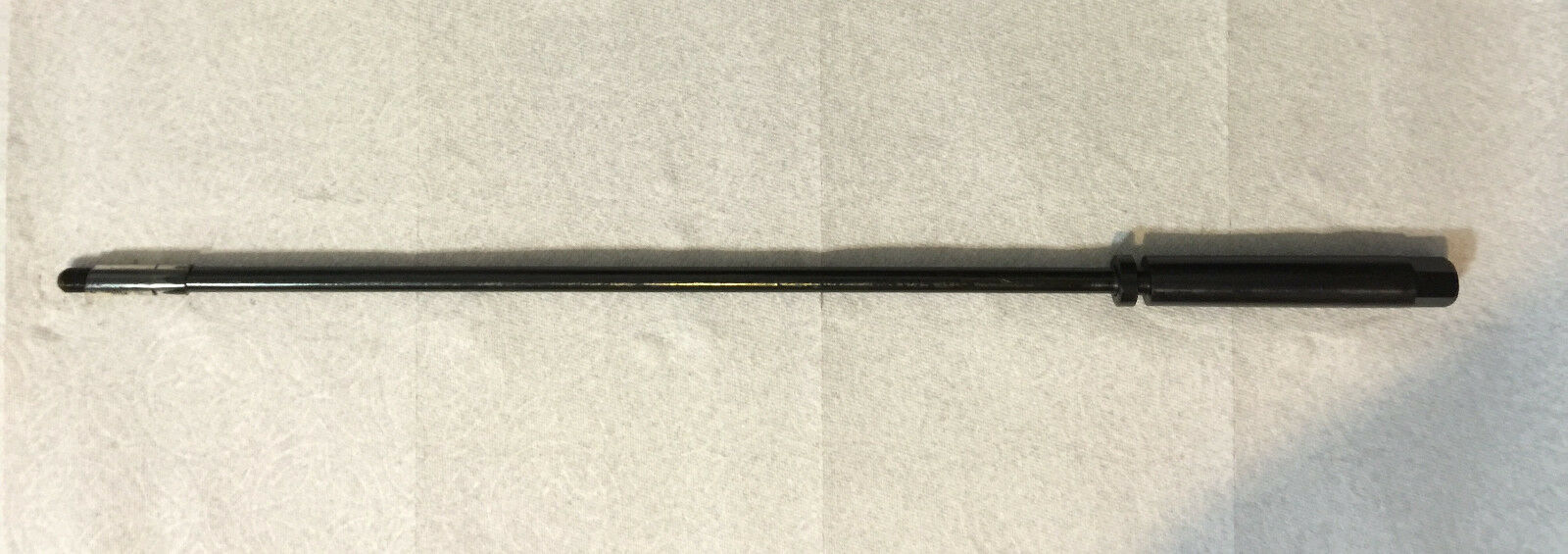

Metal pulley loaded with ball bearing, pivot yoke, bronze pivot bushing and additive manufacturing column adapter machined to accept a bronze bushing and securing hardware. This item is made by me including sourced and modified parts. The drill press and belts shown are props used to show application of slow speed update kit and not included.

Don't buy this hoping it will fit. MEASURE THE BORE of your column. If your bore is different, please send me photos of your drill press, caliper measurements and model of drill press. I just might make a special one for you.

It is up to you to MEASURE YOUR COLUMN TUBE ID. This item fits 3.125" tube ID. Let me know if you need something different.